Mitigating safety risks in PV systems is an ever-present concern for asset developers, EPCs, and owners-operators. While solar monitoring software can help identify issues after a system is operational, safety risks can happen at any stage of project development, and many may be undetectable without on-site quality system-by-system review. The reality is 55% of new builds have critical or major risk factors.

This data point comes from the new SolarGrade 2024 PV Health report published by field operations software company HelioVolta. The company conducted hundreds of inspections across more than hundreds of newly built and operational commercial systems in the U.S. and Puerto Rico.

Overall, HelioVolta discovered that 72% of these site health audits found critical and/or major safety issues.

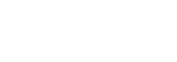

Critical issues, as defined by HelioVolta, are those that require immediate remediation, preferably before leaving the site. Major issues are immediate risks that should be fixed promptly in operating assets, or prior to handoff for new construction.

Here’s what else HelioVolta found in their new report, and what asset stakeholders can do to help mitigate these risks:

By the Numbers: Key PV System Safety Risks and Sources

Last year, HelioVolta released the first edition of its SolarGrade PV Health report, which found that 62% of inspected systems had major or critical issues. Unfortunately, this year’s report saw a 10% increase in these issues.

HelioVolta clarifies this increase is partially due to its database doubling in growth, and that 40% of its inspections occurred at randomly selected locations that had histories of previous safety issues or failures. However, no PV asset developer, EPC, or owner/operator wants to hear that solar safety risks have grown over the last year.

Where and why are these issues happening? HelioVolta highlighted some key discoveries:

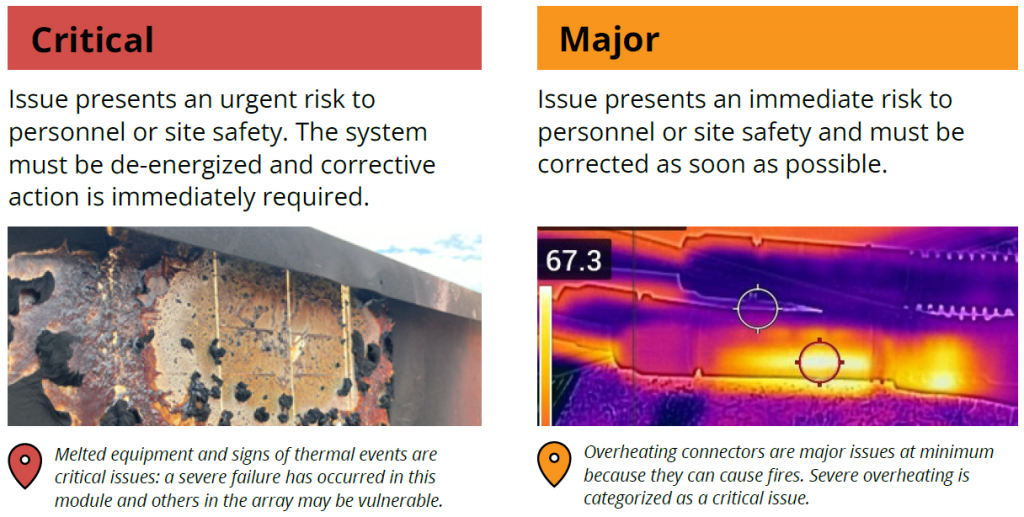

1. Almost 80% of critical issues occurred in operating systems.

A total 70% of all critical issues came from thermal failures, hotspots, overheating, and thermal damage.

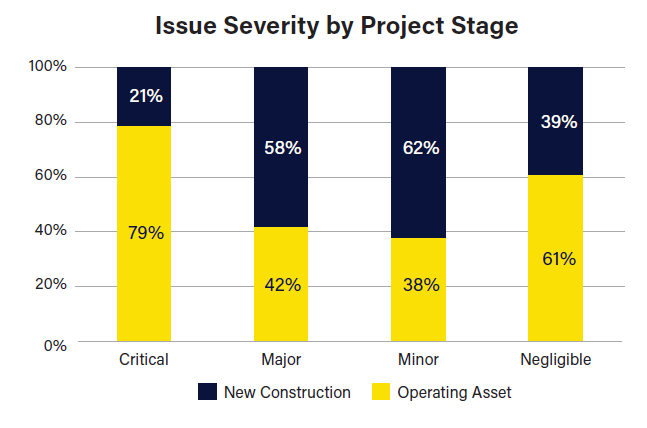

2. 56% of major issues came from DC distribution errors.

These major issues were more likely to occur in new builds and projects.

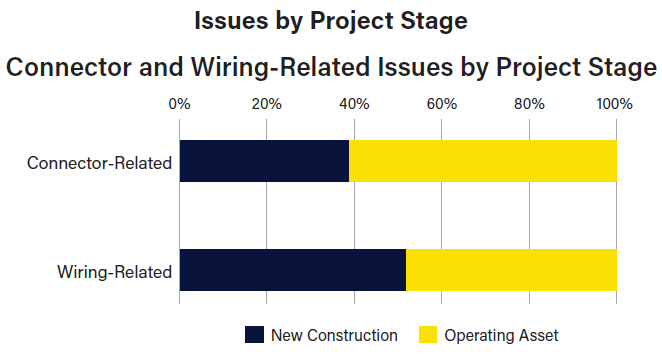

3. Wiring and connection concerns were the dominant problem across all types and sizes of systems.

A staggering 80% of projects saw wire issues and 83% saw connector issues. To clarify best practices for installation and operations and maintenance (O&M), HelioVolta also recently released a white paper on wire management standards.

QA/QC, Monitoring, and Standardization Can Reduce Risks

What can solar project stakeholders do to reduce their chances of experiencing these safety concerns? HelioVolta revealed several opportunities in their report:

1. Invest in Robust QA/QC Inspections

Stakeholders can reduce critical issues on operating systems by performing thorough QA/QC inspections during construction and handoff. HelioVolta also suggests requiring twice-yearly inspections during O&M visits after operations start.

“QA/QC for commercial solar assets plays a crucial role in transitioning from the EPC to the Asset Management phase of the asset lifecycle or when a transaction results in a change of ownership,” Omnidian’s former Vice President of Commercial Operations Anna Waters explained.

“This service ensures compliance with code requirements and safety standards, verifies the accuracy of as-built drawings, and identifies installation deficiencies. The QA/QC report provides a punch list of issues that need to be addressed before the project reaches final completion or ownership changes.”

“This process ultimately helps maintain high quality and safety standards in solar projects, supporting better performance and return on investment for solar assets,” she added.

[QA/QC] ultimately helps maintain high quality and safety standards in solar projects, supporting better performance and return on investment for solar assets.

– Anna Waters, former Vice President, Commercial Operations at Omnidian

2. Identify Issues Rapidly with Monitoring

For post-installation safety needs, it’s important to monitor assets on an ongoing basis for any performance and safety issues that need to be remediated. This is particularly important for any components that are prone to degradation or faults.

It’s also helpful to get a consistent understanding of your assets’ performance and how it relates to downtime vs. potential safety issues. Solar panel monitoring software can provide this additional layer of insights that QA/QC can’t always identify. A robust monitoring platform is useful for prioritizing remediation efforts, as it helps identify which alerts might be linked to safety concerns requiring attention.

“Continuous remote monitoring is an essential tool that enhances and supports on-site system inspections and maintenance,” said Stephanie Graham, Omnidian’s Director of Client Success.

“While QA/QC and technician visits capture a snapshot in time, remote monitoring empowers asset owners and managers to track the health of system components throughout their entire lifecycle. This approach is a cost-effective method for assessing at-risk assets and identifying potential equipment failures, enabling timely remediation.”

3. Standardize Industry-Wide “Risk” Definitions

At a philosophical level, HelioVolta believes all solar stakeholders need to align on what differing levels of “risk” mean. Despite some professionals using the same terms across their projects, the solar industry as a whole “lacks unified, objective standards for assessing the risk of failure in PV systems.”

This lack of consistency across risk definitions can lead to a host of problems. For example, if the severity of a risk is argued among stakeholders, a solar project’s development could be delayed or legal processes could take place. And if high risk situations are understated by any involved party, others won’t understand the urgency of taking corrective actions to avoid safety incidents.

Once the industry is more unified on these terms, site visits can become standardized across the board. Consistent definitions will not only contribute to more accurate reporting and documentation, but will also help reduce the amount of safety risks many system owners and operators face today.

Solar Monitoring Software for Safety Mitigation

If you’d like to see more data from HelioVolta’s report, you can read the full version here. And if you want to protect your solar investments post-installation and keep a pulse on potential safety risks, Omnidian’s solar monitoring software can help your commercial systems thrive.